Back to Manufacturing Open CourseWare

Preview Online Program: NSC Composites Technology Certificate Program

Audience: Instructional designers, Industry training and students

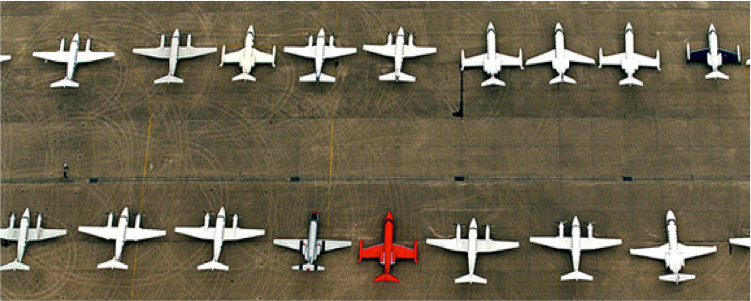

The National STEM Consortium academic certificate in Composites Technology is built on a 30-semester-credit model and includes two tracks: (1) Composites Fabrication, Assembly, and Repair, and (2) CNC Machining and Composite Manufacturing. Graduates are prepared for entry-level positions in industries including aviation, marine, recreation, green energy, and manufacturing.

Subject Matter Expert Review ![]()

SME Reviews: NSC Composites Technology Certificate

Program Guide ![]()

NSC Composites Technology Certificate Program

Courses In This Program

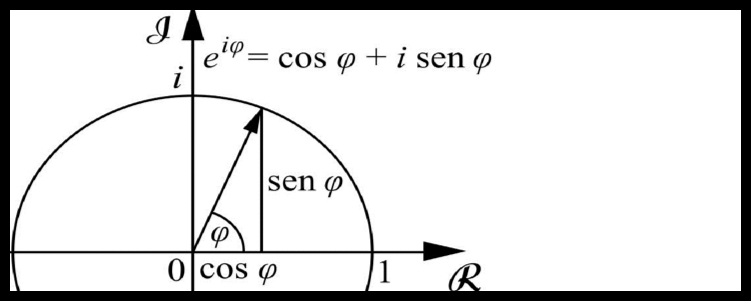

Applied Math

Applied Math consists of sixteen lessons along with corresponding supplemental labs and/or class activities. Topics covered include: whole number operations, fraction and decimal notation, ratio, proportion, percentages, exponents, scientific notation, basic algebra, measurement, introductory physics, geometry, triangle and trigonometry topics, area, volume, and the Cartesian coordinate system. Students will also enhance their professionalism skills which are assessed using a professionalism rubric.

Preview Online Course: Applied Math

Download Materials: NSC Composites Technology Certificate Program – Applied Math

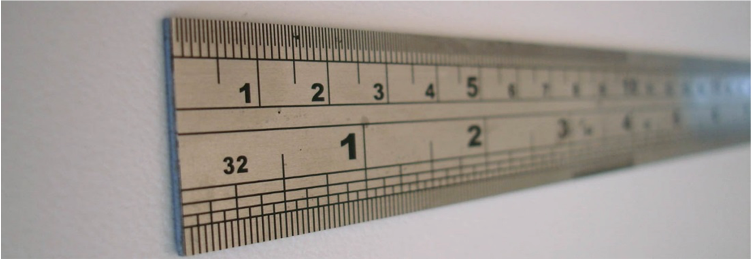

Semi Precision and Precision Measurement

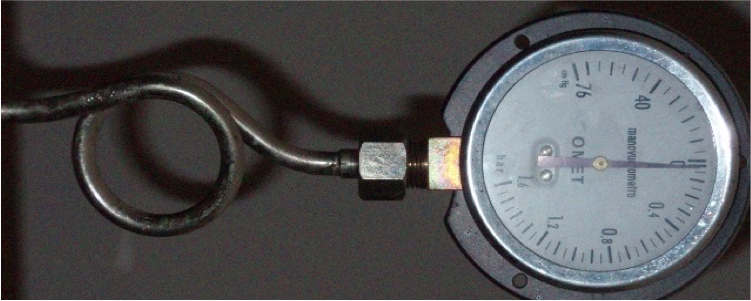

Semi Precision and Precision Measurement is the study and practice of measurement tools common to Composites and Machining. It is a fundamental skill required in fields where part tolerances rely on precision. This course consists of five lesson plans along with corresponding labs and/or class activities, and supplemental materials. The course also includes two online modules that are designed to help students through common sticking points and better prepare them for face-to-face instruction. Topics covered include: the care and handling of semi-precision and precision instruments, the difference between semi and precision measurement, and the introduction and practice of several measurement instruments.

Preview Online Course: Semi Precision and Precision Measurement Introduction

Download Materials: Semi Precision and Precision Measurement

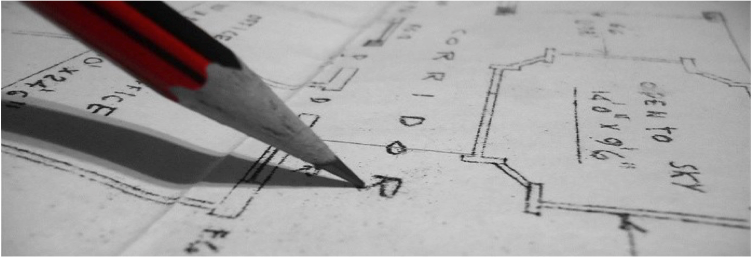

Drawings and Prints

Drawings and Prints is the study of foundational blueprint and drawing skills. These skills are necessary in machining and in composites technology as the technician may be required to identify the sizing, the shape, and the material make-up of an object. Topics covered include: A working knowledge of the alphabet of lines, including: object lines, hidden lines, center lines, extension lines, dimension lines, and projection lines. The course will cover blueprint views and how they are arranged: one view drawings, two view drawings, and standard three view drawings, as well as auxiliary views. Students will practice dimensioning procedures on basic blueprints, including: size and location dimensions, dimensions in limited space, dimensioning holes, cylinders, arcs, and angles. They will define and use unilateral and bi-lateral tolerances as well as classes of fits.

Preview Online Course: Drawings and Prints

Download Materials: Drawings and Prints

Professionalism

Professionalism provides the knowledge and skills necessary to successfully navigate a career in the field of composites. Skills covered are necessary behaviors, habits, and documentation necessary to gain employment, navigate an organization, and advance in this career path. The modules of this course are intended to be taught throughout the certification pathway to support the growth of the individual as a professional. Topics include industry relevant resumes, transferable skills, online job-search, online professional presence, interview skills, professional development using fully-online classes, motivational theory, leadership, group dynamics, organizational theory, conflict management and behavior modification in order to improve effective communication, and effectiveness and group dynamics in the workplace and other organizations.

Preview Online Course: Professionalism

Download Materials: Professionalism

Safety

Safety is a general overview course on safety; it covers the fundamentals of environment, health, and safety topics required to become a successful composites technician. Additionally, in-depth and specific environment, health, and safety issues, policies, procedures, and regulations are discussed throughout this program. Industry leaders were part of the curriculum design of the course determining the basic knowledge and skills needed to be a safe and viable candidate for employment. Topics covered include: hazardous communication, ergonomics, regulations, standard operating procedures (SOP), personal protective equipment, lockout/tagout, hand and power tool safety, and industrial housekeeping.

Applied Physics

Applied Physics is a study of the underlying physical principles encountered when kitting, repairing, or maintaining composite parts in the aviation industry, or in other industries, such as marine. This course consists of six lessons along with corresponding supplemental labs and/or class activities. Topics covered include: weight, mass, gravity, energy, force, work, power, machines, stress, motion, heat, pressure, gas laws, fluid mechanics, and the forces of flight.

Preview Online Course: Applied Physics Introduction

Download Materials: Applied Physics

Materials and Processes

Materials and Processes provides the introductory knowledge and skills necessary to work with metal and nonmetallic materials and various forms of hardware. This course also introduces inspection methods and LEAN concepts. The basic knowledge gained in this course is transferable to other industries and applications. This course is to be taught in conjunction with Composites Technician Lab A.

Preview Online Course: Materials and Processes

Download Materials: Materials and Processes

Introduction to Composites

Introduction to Composites reviews the components of composites, including mechanical advantage, vocabulary, manufacturing and repair techniques and employment opportunities in the composite industry. This course consists of three lessons along with corresponding supplemental labs and/or class activities. This course provides a breadth of instructional materials and activities from which to choose. It is intended as a broad overview of the Fabrication, Assembly, and Repair Track.

Preview Online Course: Introduction to Composites

Download Materials: Introduction to Composites

Composites Lab Tech A

Composites Lab Tech A is a portfolio of project-based work required for the successful composites technician. It is offered concurrently with Semi-Precision and Precision Measurement, Safety, Blueprints and Drawings, Materials and Processes, and Introduction to Composites, and reinforces skills taught in those courses. The student will create increasingly complex projects to gain mastery in the proper use of tools, materials and processes, prints and drawings, fabrication, assembly and repair of various metal, non-metal and composite materials.

Preview Online Course: Composites Lab Tech A

Download Materials: Composites Lab Tech A

Advanced Composites Fabrication and Assembly

Advanced Composites Fabrication and Assembly hones the knowledge and skills necessary for composite fabrication, including print reading, project planning, layout, distortion control, and fixturing. The course also provides the knowledge and skills necessary for the identification and use of appropriate materials and processes to assemble structures made of composite materials. These are the first and second components in the specialty pathway of the Composite Technician Certificate curriculum, and taught in conjunction with Composites Technician Lab B.

Preview Online Course: Advanced Composites Fabrication and Assembly

Download Materials: Advanced Composites Fabrication and Assembly

Advanced Composites Repair

Advanced Composites Repair provides the knowledge and skills necessary to inspect, test, and repair composite structures. Emphasis is on structural and nonstructural evaluation, material handling, surface preparation, and repair procedures. This course is the third component in the specialty pathway of the Composite Technician Certificate curriculum, and is to be taught in conjunction with Composites Technician Lab B. This course presumes that the student has had an introductory overview course that broadly describes composite fabrication, assembly, and repair. Students will develop an in depth understanding of composite repair knowledge and related skills such as basic core materials, adhesive bonding and fastening, repair of composite structures, inspection and test methods, molding methods and practices, and tooling.

Preview Online Course: Advanced Composites Repair

Download Materials: Advanced Composites Repair

Composites Lab Tech B

Composites Lab Tech B is the final component in the specialty pathway of the Composite Technician Certificate curriculum. The student will create ever more complex projects to gain mastery in the proper use of tools, materials and processes, prints and drawings and fabrication, assembly and repair of various composite and advanced composite materials. Running parallel with the Composite Fabrication & Assembly and Composite Repair courses, these labs provide hands-on, experiential learning using projects that involve and build upon what students have learned in the Composite Fabrication & Assembly and Composite Repair courses.

Preview Online Course: Composites Lab Tech B

Download Materials: Advanced Composites Repair

Machine Tool Theory

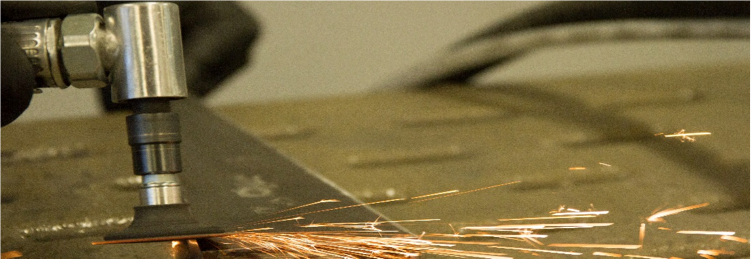

Machine Tool Theory is a foundation for study of manufacturing methods, processes, related equipment, and tools of industry. It requires the student to understand shop safety practices, job planning, machining feeds and speeds, precision measuring instruments, layout tools and procedures, hand tools and bench work, metal cutting saws, drilling machines, metal lathes, milling machines, surface grinders, and abrasives.

Preview Online Course: Machine Tool Theory

Download Materials: Machine Tool Theory

Machine Operations Lab

Machine Operations Lab introduces hands-on learning for three different types of machine tools: vertical milling machine—Bridgeport-type, metal lathe, and surface grinder. Blueprint reading, math, 3-D spatial, and mechanical aptitude are integrated into the hands-on projects. The course covers how to safely and effectively operate machinery, use proper terminology for all items, precision measurement, layouts, print reading, machine set-ups, hand tools, measuring tools, cutting tools, and all other processes in production work flow. Selected lab equipment is typically found in most conventional machine shops. The required extensive hands-on projects are especially attractive to prospective employers looking for students with machining experience.

Preview Online Course: Machine Operations Lab

Download Materials: Machine Operations Lab

CNC Machining

CNC Machining will review and cover the fundamental Computer Numerical Control (CNC) Machining topics required to become a successful composites technician. These include: the Cartesian coordinate system, AutoCAD (which is a commercial software application for 2D and 3D Computer-Aided Design – CAD), G-Codes (CNC programming language), M-Codes (machine code multi-paradigm numerical computing environment programming language), Program Writing, Simulation Software, Safety Procedures, Machine Set-up and Operation, program loading, execution, and error checking.

Preview Online Course: CNC Machining

Download Materials: CNC Machining

Injection Molding

Injection Molding is an overview of the process and types of polymers and composite materials used by today’s manufacturers. The course covers the techniques and procedures used in the set-up, operation, and processing of molded parts including: injection mold machine set-up, injection pressures, press temperatures, clamping pressures and secondary machining operations of completed parts.

Preview Online Course: Injection Molding

Download Materials: Injection Molding