Back to Manufacturing Open CourseWare

Preview Online Program: NSC Mechatronics Technology Program

Audience: Instructional designers, Industry training and students

The National STEM Consortium academic certificate in Mechatronics Technology is built on a 30-semester-credit model and is mapped to the Siemens Mechatronic Systems Level 1 certification. The skills taught include electrical, mechanical, and computer technologies. Graduates are prepared for entry-level Mechatronics positions in almost every industry.

Subject Matter Expert Review ![]()

SME Review: Mechatronics Technology Program

Program Guide ![]()

NSC Mechatronics Technology Program

Courses In This Program

Autonomous Robots

Autonomous Robots is a lab-based course that introduces the basic concepts of robotics, focusing on the construction and programming of autonomous mobile robots. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include the basic principles of mechanical robot construction, electronics, sensors, motors, and robot programming; troubleshooting techniques and strategies to identify, localize, and correct malfunctions; and safety and systematic preventative maintenance. In addition, students will work in groups to build and test increasingly more complex mobile robots.

Preview Online Course: Autonomous Robots

Download Materials: Autonomous Robots

Engineering CAD & Drafting

Engineering CAD and Drafting is a survey course that covers CAD modeling and drafting techniques specific to mechatronic systems. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include sketching techniques, multi-view drawings, dimensioning, solid-modeling techniques, documentation drawings, file management, drawing standards, and assemblies. The course embeds preparation for the SolidWorks Associate (CSWA) exam, and culminates in a mechatronic-specific CAD project.

Preview Online Course: Engineering CAD and Drafting

Download Materials: Engineering CAD and Drafting

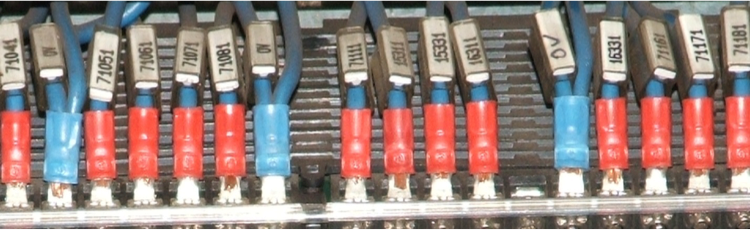

Electrical Systems

Electrical Systems is a study of the basic electrical components in a complex mechatronics system. This course discusses basic functions, physical properties, and roles of electrical components and systems, such as transformers, electric circuits, and AC and DC motors; troubleshooting techniques, such as strategies to identify, localize, and correct malfunctions; systematic preventative maintenance; and electrical and mechanical component safety.

Preview Online Course: Electrical Systems

Download Materials: Electrical Systems

Industrial Robots

Industrial Robots is a study of the working of mechanical manipulators in a safe manner and the uses of industrial robots in manufacturing. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include robotic nomenclature, classifications, applications, input/output sensor interfacing, and work cell design; different methods for programming an industrial robot using manufacturer software and for computing the spatial positions, orientation, and frames of a robot manipulator design; troubleshooting techniques and strategies to identify, localize, and correct malfunctions; and safety and systematic preventative maintenance.

Preview Online Course: Industrial Robots

Download Materials: Industrial Robots

Introduction to High-Tech Manufacturing

Introduction to High Tech Manufacturing is a study of the basics of process control and automated manufacturing processes. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include safety, ergonomics, and hazard communication; measurement devices, simple machines, and basic electrical and fluid power systems; manufacturing efficiency techniques and industrial supply chain systems; troubleshooting techniques and strategies to identify, localize, and correct malfunctions; and total productive maintenance and quality improvement systems.

Preview Online Course: High Tech Manufacturing

Download Materials: High Tech Manufacturing

Introduction to Manufacturing Processes

Introduction to Manufacturing Processes is a study of the technical knowledge required for the selection, design, and planning of manufacturing processes and systems. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include basic safety; the benefits, limitations, and applications of different machine tools and engineering materials for product manufacturing safety; the adaptability of machinery to a variety of manufacturing processes; and the parameters surrounding processes, machinery, and operations that influence design considerations, product quality, and production costs.

Preview Online Course: Introduction to Manufacturing Processes

Download Materials: Introduction to Manufacturing Processes

Mechanical Systems

Mechanical Systems is a study of the basic mechanical components in a complex mechatronics system. This course discusses basic functions, physical properties, and roles of mechanical components, such as materials, lubrication requirements, and surface properties; troubleshooting techniques, such as strategies to identify, localize, and correct malfunctions; technical documentation, such as data sheets and specifications of mechanical elements; systematic preventative maintenance; and electrical and mechanical component safety.

Preview Online Course: Mechanical Systems

Download Materials: Mechanical Systems

Mechatronics Capstone

Mechatronics Capstone is a hands-on study of the control, maintenance, and simulation of automated processes. This course consists of four lessons along with corresponding labs and/or class activities. The physical systems substations include processes such as pick and place feeding, automatic gauging, part indexing, part sorting and queuing, and robotic pick and place assembly; software simulation of each substation also are presented. The final project consists of the complete software and hardware integration of all subsystems into a fully functional mechatronics system. The course also embeds preparation for an industry-recognized mechatronics certification.

Preview Online Course: Mechatronics Capstone

Download Materials: Mechatronics Capstone

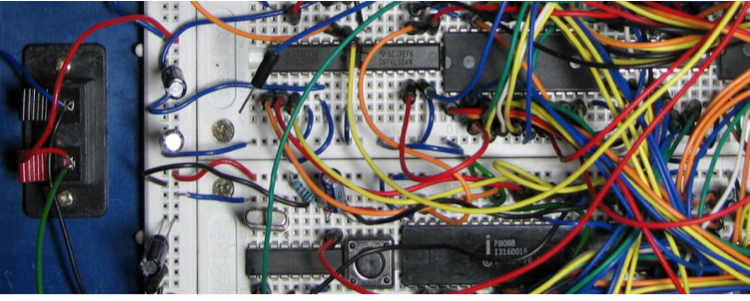

PLC’s 1

PLCs 1 is a study of the basic digital logic and programmable logic controllers (PLC) in a mechatronics system using the automation system. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include basic PLC functions and testing; industrial applications of PLC requiring motion control; troubleshooting techniques and strategies to identify, localize, and correct malfunctioning PLCs; and writing small programs and problem-solving using computer simulations.

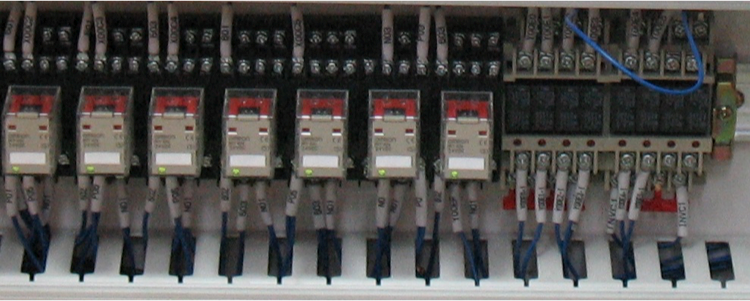

PLC’s 2

PLCs 2 is a study of the concepts, programming, and applications of a programmable logic controller (PLC) in a mechatronics system using the automation system. This course consists of 12 lessons (and two optional lessons), along with corresponding labs and/or class activities. Topics covered include industrial applications of PLCs requiring programming; timers, counters, and subroutines, as well as event-driven and time-driven sequences; and troubleshooting techniques and strategies to identify, localize, and correct malfunctioning PLCs. Practical laboratory experiments reinforce the topics of ladder logic diagrams and programming PLCs.

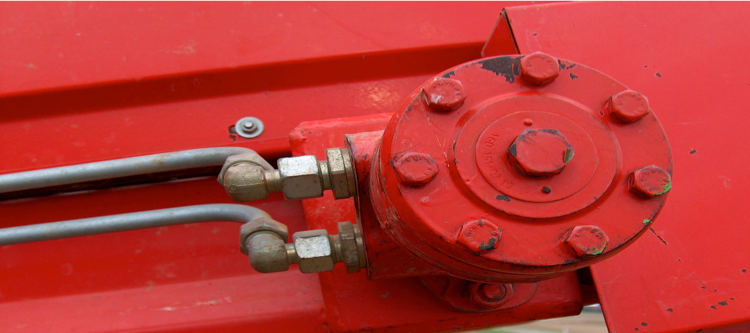

Pneumatics and Hydraulics

Pneumatics and Hydraulics is a study of fluid power technology using fluids or compressed air as the transfer media. This course consists of 15 lessons along with corresponding labs and/or class activities. Topics covered include basic functions and physical properties of complete hydraulic and pneumatic systems, such as power sources, reservoirs, pumps, compressors, lines, valves and actuators; troubleshooting techniques and strategies to identify, localize, and correct malfunctions; and safety and systematic preventative maintenance.

Preview Online Course: Pneumatics and Hydraulics

Download Materials: Pneumatics and Hydraulics

Welding

Welding is a study of the processes and methods for joining various materials. This course consists of 20 lessons along with corresponding labs and/or class activities. Topics covered include safety; basic mechanical properties of electrodes; methods and techniques for cutting, welding, and testing; systematic preventative maintenance; and the certification qualifications of welders.

The course embeds preparation for the 2F American Welding Society (AWS) Certification Test and provides students with the opportunity to take the test on the last day of the course.